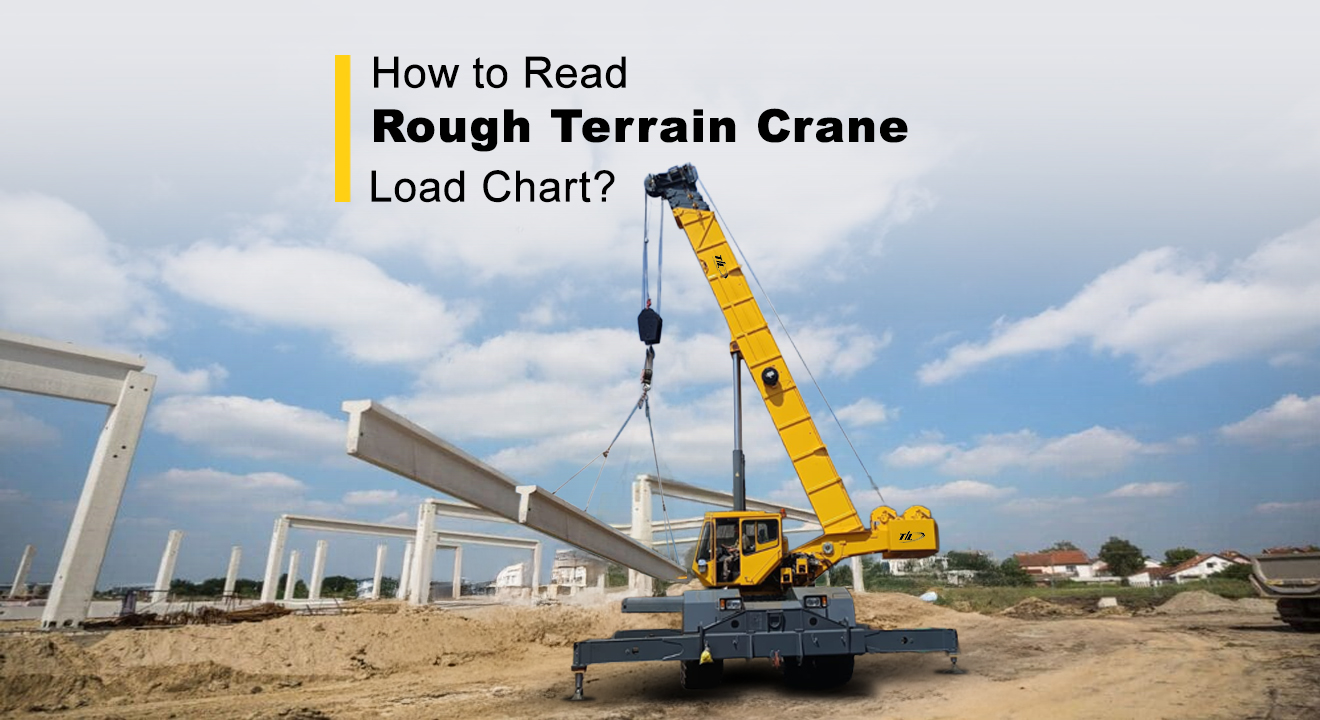

If you read a crane load chart incorrectly, you could be on the verge of a major accident. One incorrect number determines the difference between a safe lift and a safety violation.

These charts are therefore more than just the numbers in rows and columns that were written on the specification sheet. Every safe lifting operation depends on them. They outline precisely what a crane can and cannot manage in specific conditions.

However, many site supervisors and new operators initially find them confusing.

You can read a crane load chart with confidence if you follow this guide, which will cut through the jargon. You will be able to understand not only the meaning of the numbers but also their importance.

Why Do Crane Load Charts Matter?

Every crane has limits, and if you try to push past them, you risk tipping the crane. Your one wrong decision could also result in major safety incidents or equipment damage.

These boundaries are specified in a crane load chart. You can determine the exact quantity that the crane can lift under specific circumstances by using the load chart. Now, several variables affect the crane's lifting capacity, such as:

- ⚫ Boom length

- ⚫ Boom angle

- ⚫ Working radius

- ⚫Configuration - whether you are using outriggers or rubber, jib extensions, or counterweights.

In short, the load chart ensures that every lift stays within the safe range of the crane. Without it, you are not just working blindly, but you are working in an unsafe zone.

Think of it this way: A crane's lifting capacity isn't one fixed number, and it changes constantly depending on how you use it. Moreover, every crane model has its own unique load chart. Even two cranes of similar lifting capacity from the same manufacturer can have very different load charts if their specs differ.

Are Load Charts Specific to Make and Model?

Yes, load charts are specific to make and model. The manufacturer creates the load chart for each crane after conducting thorough engineering research and rigorous testing to determine the safe lifting limits. Charts can differ significantly even among cranes with the same rated capacity.

For instance, both a 60-ton rough-terrain crane and a 60-ton hydraulic truck crane may be marked "60-ton". However, their lifting capacities differ according to their design, boom structure, and operating setup.

Breaking Down the Rough Terrain Crane Load Chart

Let's walk through the key elements you'll find on most crane load charts:

1. Crane Configuration

Before looking at any numbers, you need to understand how the crane is set up. The chart will specify details such as:

- ⚫ Outrigger position (fully extended, partially extended, or on rubber)

- ⚫ Counterweights installed or removed

- ⚫ Boom length and type (main boom or jib extension)

Each setup alters the crane's safe lifting capacity.

2. Rated Capacity

This is the maximum weight the crane can lift within a certain boom radius and length. The crane's rated capacity is its assured safe limit under ideal conditions. However, it does not specify the breaking point of the crane. Moreover, it also includes safety considerations set by the manufacturer.

3. Load Radius

The crane's lifting capacity decreases as the load moves farther from the center pin. For example, a TIL's RT 740B crane could lift 40,000 kg within a 3-meter radius, but 14,100 kg at 8 meters.

4. Boom Angle and Length

The boom angle has an impact on the load's outward extension. The lifting capability decreases with a longer boom or a lower angle. Thus, whenever the boom setup is changed during a job, the operator must always double-check the chart.

5. Notes and Warnings

There are also footnotes for deductions, such as hook block, and others, which are included in the crane load charts. You must never ignore these minor details, as this might quickly result in overloading issues.

How to Read Crane Load Charts in Practice?

Let's go step by step with a real-world example.

Imagine you're using a rough-terrain crane (RT740B) with a 33.5 m main boom. The load is 15000 kg, and it needs to be set at a 7-meter radius.

- 1. Check the configuration – Are outriggers fully extended? Counterweights installed?

- 2. Find the right boom length column – In this case, 10.6 meters on outriggers.

- 3. Match the load radius row – Look at 7 meters.

- 4. Read the rated capacity – Suppose it shows 17,050 kg. Perfect, then you are under the limit.

- 5. Deduct weight for rigging & the numbers can be found from the spec sheet

In case higher lifting is required at the same radius and boom length, you could either bring in a larger crane or alter the crane setup.

Common Mistakes to Avoid

Even the best operators slip up sometimes, and when it comes to crane load charts, small mistakes can have big consequences. Here are some of the most common ones to watch out for:

1. Ignoring rigging weight

Those hooks, slings, and spreader bars aren't weightless. Always subtract their weight from the crane's rated capacity, or you could end up overloading the crane without realising it.

2. Mixing up gross and net capacity

The numbers on the chart show gross capacity. You still need to figure out the net capacity after deducting rigging and attachments. This is one of the most common errors on the site.

3. Forgetting about boom extensions

Add a jib or change your boom setup, and the whole chart changes. A longer reach usually means less capacity, so always check the updated chart before you lift.

4. Overlooking outrigger setup

A crane sitting on rubber doesn't lift anywhere near as much as one on fully extended outriggers. Always verify the setup before relying on those numbers.

5. Trusting memory instead of the chart

Conditions change from job to job, which includes the boom length, angle, load radius and more. Never guess. So, always double-check the chart before every lift.

Final Word

Crane load charts aren't just paperwork; they're life-saving tools. Every safe lift starts with understanding and respecting those numbers. If you're in the crane industry, knowing how to interpret crane load charts isn't optional; it's essential.

Whether you're a new apprentice or a seasoned operator brushing up on best practices, keep the load chart close, read it carefully, and never cut corners.

At With TIL Limited, we ensure top tier lifting performance by providing proper training and guidance during equipment commissioning. Our commitment to reliability, safety, and long-term efficiency is reinforced by using only genuine OEM parts to replace worn components.